Difference Between Hydraulics and Pneumatics

Non-engineers often confuse hydraulics and pneumatics to be one and the same thing, but an engineer finds the two to be substantially different. While both the systems are an application of fluid power, hydraulics involves the utilisation of pressurised fluids in to control or harness power, whereas pneumatics involves the uses of incompressible fluid. Hydraulics and pneumatics also differ on account of the pressure that is required during operation, with the former requiring far more pressure than the latter. Bigger components are used in hydraulic applications as compared to pneumatic application, which also contribute to the greater difficulty in operating hydraulic systems as compared to pneumatic applications.

Instructions

-

1

Hydraulics

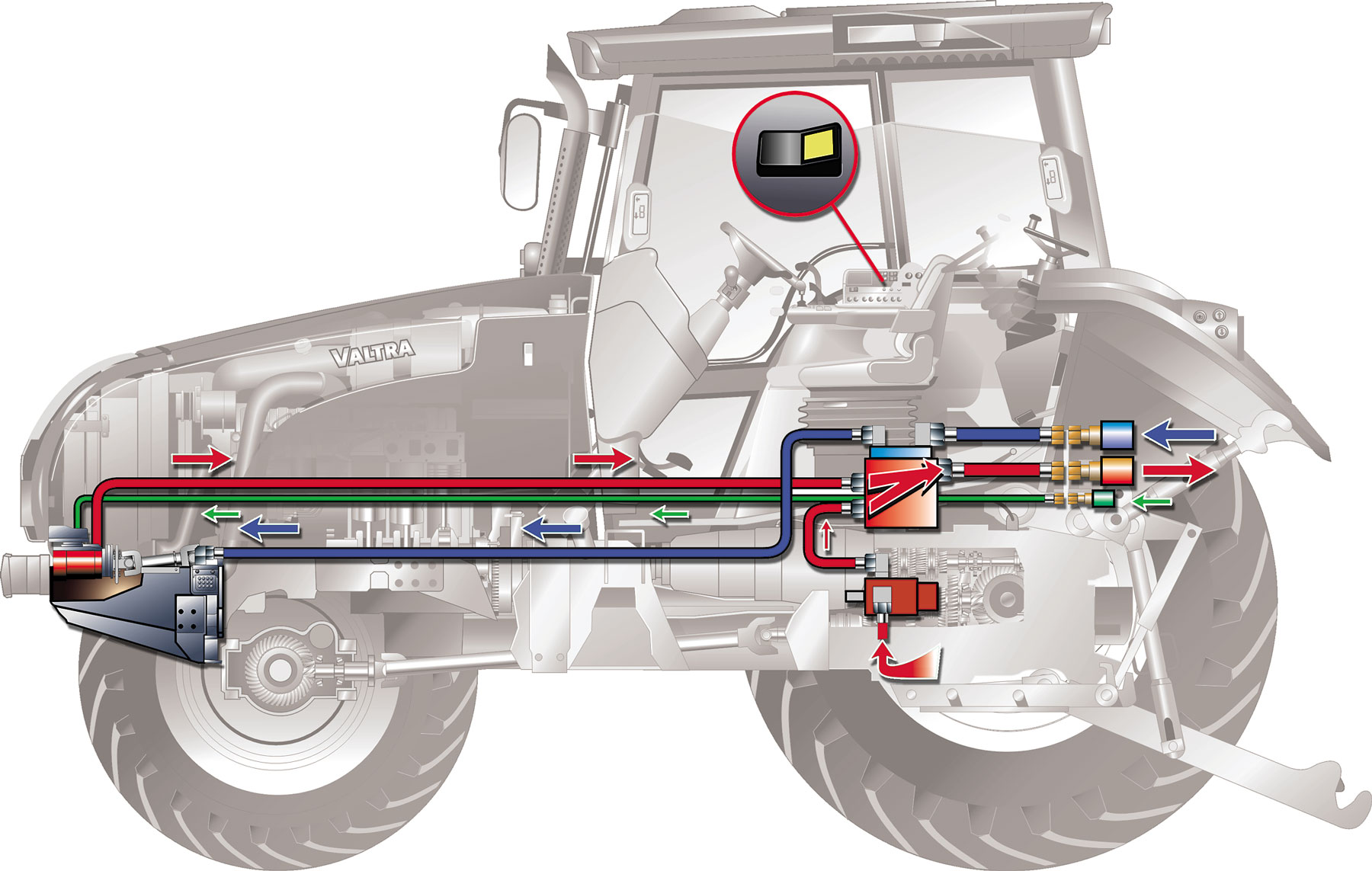

Hydraulics can be defined as a system or an application of power fluid that involves the utilisation of pressurised or incompressible liquid media such as water or oil to control, transmit and harness power. Hydraulics is typically applied while analysing dams, turbines, rivers, erosion-hit areas, etc. Hydraulic systems use a huge amount of pressure in its operations. The pressure demanded by the hydraulic-based applications typically ranges from 1000 to 5000 psi (pound force per square inch). Advanced hydraulic-based systems may demand up to 10,000 psi. This demand for huge amount of pressure in operation results in the system depending on large components. The large components involved in the operation of hydraulic systems are pretty complicated to operate and require a fair bit of technical know-how. There are some hydraulic-based devices that are automated and therefore relatively easier to operate, but of course, automated hydraulic-based devices are extremely expensive.

-

2

Pneumatics

Pneumatics can be defined as a study of the influence or impact of pressurised gases on mechanical movement of motion. The system is frequently applied in dentistry, general construction, mining, and various other fields. Pneumatic system makes use of compressible gas such as air itself, though the use of a pure gas is considered to be more appropriate. Industrial applications of pneumatics demands pressure in the range of 80 to 100 psi, which is not considered to be a very high demand. The amount of pressure required for the pneumatic-based application make it possible for relatively compact components, which are fairly simple to use. Operators of the pneumatics system liken the simplicity of operating the pneumatics to that of a light switch, which just needs to be switched on and off through two simple choices. Some pneumatic devices are even simpler to use as the whole system is automated.

- Image Courtesy: mindsetsonline.co.uk