Difference Between Tensile Strength and Yield Strength

Yield strength and tensile strength are two very important concepts discussed in material science and several branches of engineering, including structural engineering and mechanical engineering. Yield strength is defined as the maximum amount of stress a material can withstand before it starts undergoing plastic deformation. Tensile strength, on the other hand, is the measurement of the maximum amount of deformation a certain material can tolerate without breaking or failing.

Since both yield strength and tensile strength are levels of stress, most people, especially novices, confuse them and often use them interchangeably. However, they are two distinct terminologies related to mechanics, the branch of physics which is concerned with the behaviour of material when it is subjected to forces or displacements.

Yield strength is the strength or the amount of stress where the deformation turns from temporary or elastic deformation to permanent or plastic deformation – in simple words, it is the lowest stress beyond elastic limit at which permanent deformation will occur. Tensile strength, on the other hand, is the amount of stress after which the necking effect begins. The value of yield strength for a certain material is always less than the tensile strength. Every material has specific values of yield strength and tensile strength.

Instructions

-

1

Yield strength

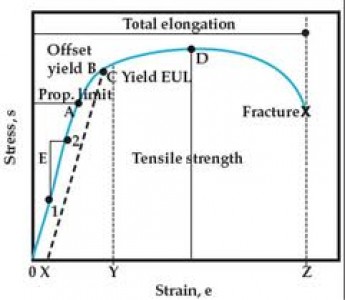

In mechanics, the yield strength of a material is defined as "the stress at which a material begins to deform plastically". Whenever an external force is applied to stretch a material, the first part of the stretching is elastic; this means that any change to the material is reversible and the material gets back to its original shape soon after the external force is removed. This is called elastic deformation.

However, if you continue to increase the force, there comes a point after which the deformation becomes permanent. This is called plastic deformation. The point where elastic deformation changes to plastic deformation is very important, especially from the mechanical and structural engineering perspective. If the applied stress is lower than the yield strength, the deformation will always be elastic; however, once you pass this point, a part of deformation will be permanent, irreversible or plastic.

Image courtesy: steel-n.com

-

2

Tensile strength

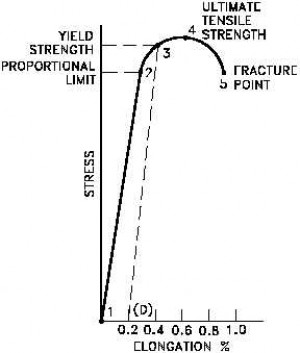

Tensile strength is defined as "the maximum stress a material can withstand, while being pulled or stretched, before necking". Necking is the stage where the area of the cross section of the material becomes significantly small.

When an external force is applied to stretch a material, the intermolecular attraction forces start acting in opposite directions in order to counter the deformation, and once the force is removed, the object fully or partially returns to its initial state. However, if the stress is strong enough to overcome the intermolecular forces, it causes a sudden strain due to which the material breaks apart. This phenomenon is called necking, and the strength applied is called tensile strength.

Image courtesy: info.admet.com