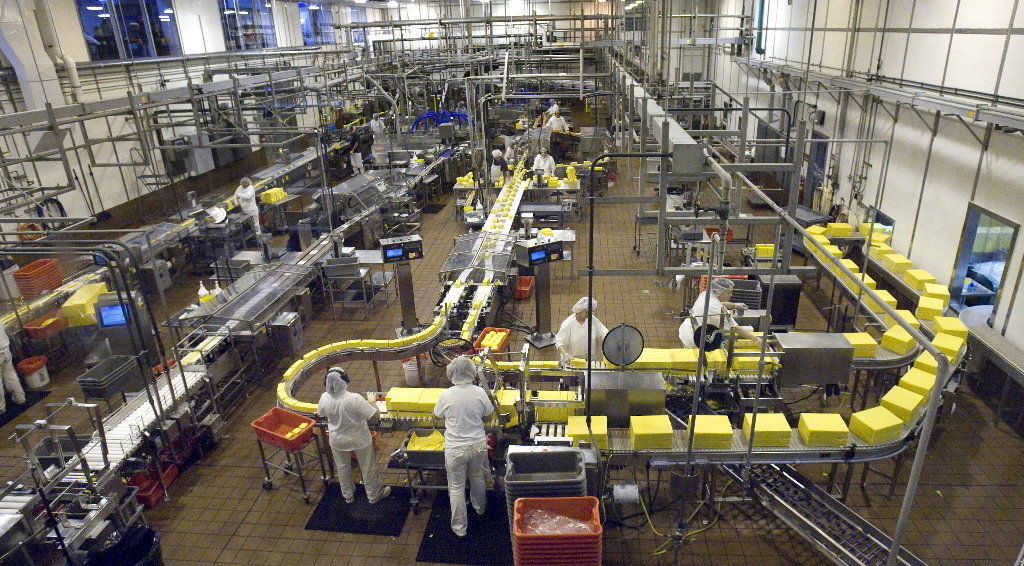

How Cheese is Made in Factory

Cheese is used in our daily life food in pizza, sandwiches, fast food and in many eating items, so it became an important part of eating. People love to add cheesy flavor in their food to enjoy the meal in a delight way. Sometime we wish to know about how actually cheese is made in factories. Making cheese is a science and art both at the same time, as cheese makers have to consider the quantities of ingredients as well as the methodology of making cheese.

Instructions

-

1

Quality Milk intake:

The very basic ingredient to make cheese is best quality milk. First of all quality of milk is tested in factories in order to make best cheese. For making one pound of cheese we need 10 pounds of quality milk.

-

2

Standardization:

In next step milk is standardized by heating, weighted processes in order to make sure of best quality cheese production. This process is very important for the protection and its long last validity.

-

3

Coagulant and Starting step:

Initially some good bacteria are added into milk, as these bacteria help to make texture and flavor of cheese. And then rennet is added for coagulate the milk, this would result to form thick milk mass.

-

4

Cutting Process:

Once milk gets thick then cutting process starts in order to separate liquid (whey) from milk solid (curds). After cutting large pieces of curds are cooked at slow heated temperature.

-

5

Stirring, Heating and Draining:

Then curds are cooked and stir for defined temperature and time.

-

6

Curd Transformation:

For transformation curd different methods are used, one of most commonly used is salting them.

-

7

Pressing:

For shaping and curd formation purposes, pressing methodologies are being used. Pressing cheese depends upon their sizes if they are big in size then there pressing time can of 12 hours but if they are small it may take 3 hours to get ready.

-

8

Curing:

This step is used to make long life validity of cheese by moving cheese in a room that is controlled carefully for humidity and proper temperature in order to develop cheese flavor. So that it can be aged up to 10 years.

-

9

Packing:

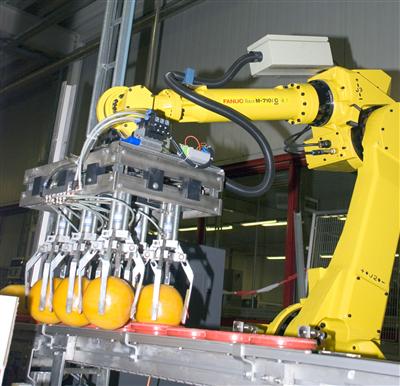

Once all processes are over, packing process gets start. Now cheese is packed according to its categories, sizes and shapes forwarded to market places.