How to Lap a Computer Processor

The latest processors come with aluminium plated caps known as Integrated Heat Spreader (IHS). This helps in reducing the heat of the processor in order to increase its efficiency.

However, there are some hidden gaps in the IHS, which don’t allow it to function properly. As a result, the processor gets heated and performs slower than normal. This appears to be a big problem, but the solution is quite simple.

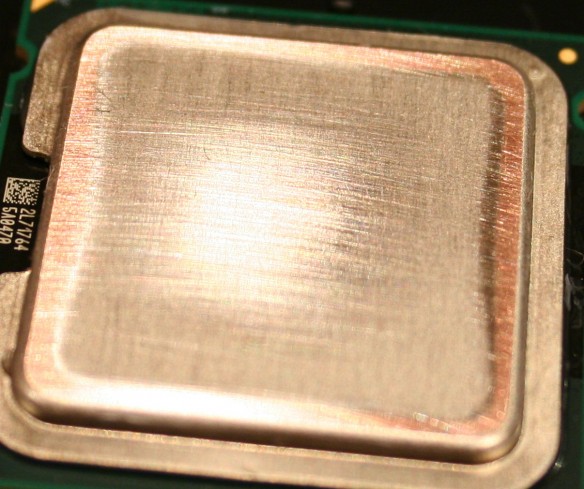

You can finish the microscopic IHS gaps by lapping the processor. This way, the copper surface will be exposed to the heat sink and help in reducing the heat. Consequently, the processor will operate more efficiently, as the temperature will reduce by more than 10 percent.

Things Required:

– Cotton swabs

– Acetone (nail polish remover)

– Sandpaper (220, 400, 600, 800, 1000, and 1500 grit)

– Flat work surface

Instructions

-

1

Use cotton swabs to remove residue

The processor will be covered by some dirt, which can easily be removed by a cotton swab. You can use any cloth too, but the former option will be a lot better. Dip the cotton swab into acetone and then gently wipe the processor. Make sure you have removed the entire residue from the surface. -

2

Glide processor over sandpaper

Take 220-grit sandpaper and place it on your workplace. Now, move the processor smoothly over the sandpaper in a circular motion. You need to apply some pressure, but make sure not to exceed limits. Keep doing this for the next 15 minutes, as it will take time to make the surface smooth. -

3

Keep checking the surface

While you are sanding, continue checking the surface in order to make sure that you are not doing anything wrong. You have to carry on with this process until the entire copper beneath the IHS is properly exposed. -

4

Stop sanding when aluminium plating is removed

After 15-20 minutes of sanding, the aluminium plating will be removed. You need to stop sanding at that point and use new 400-grit sandpaper for further process. -

5

Continue sanding until copper surface is revealed

Using increased grits of sandpaper, continue sanding the processor until the copper surface is exposed. This will take some time, so you have to be patient. -

6

Make the surface smooth

Once the surface is exposed, you have to make sure it gets smooth otherwise you will not get the desired performance. -

7

Clean the surface with cotton swabs

Once again, you will need to clean the surface with cotton swabs and acetone and leave the processor to dry out completely.