What Are the Different Types Of Actuator Controls

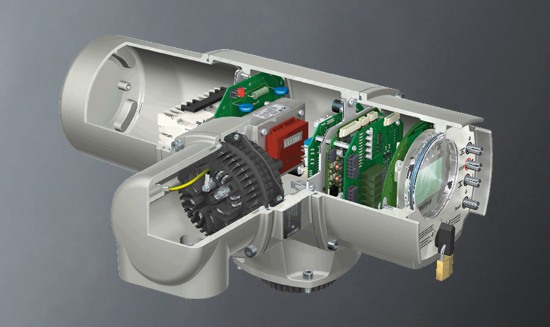

Actuator control systems are mechanism that control actuators at different levels to prevent them from over-heating and over-cycling. For example, they stop, start and protect actuators from being exposed to these steps. There are two simple types of actuator controls: those that are controlled through simple or manual methods, and those that are controlled through automated systems. Another form of controls is a multi-servo function system. In this type, the controls are performed remotely and automatically, not through the conventional manual method.

Instructions

-

1

The basic type of actuator control is performed manually. This mechanism is installed in the basic systems, where the system is accessed manually, while there it does the job as effectively as other two types. The control to be operated manually also performs the job of stopping, starting and protecting actuator from overheating and over-cycling. However, since it is manual it is less time efficient in comparison with other two types, which have greater time efficiency. The system is gradually replaced by the automated control mechanisms, especially in the big industries where automation is the centralized mechanism.

-

2

The automated actuator controls provide the remote switching option and can easily be controlled. Although any type of controls are nowadays essential equipment in the industrial installation, automated control mechanisms are more popular among the big industrial settings. These controls allow the time efficient control of actuators. In a centralized automated industrial infrastructure and equipment, the automated control mechanism is the only mechanism that can be installed. It does not make sense to install a manual actuator control in an automated industrial infrastructure.

-

3

Nowadays, a multi-servo actuator control mechanism has also been used. It allows control in a more time efficient environment, where the whole industrial infrastructure is computerized, and is controlled from remote control rooms. The multi-servo mechanism has also allowed the real time and more sophisticated control of outputs. They can be programmed to stop, start and protect automatically. This mechanism is controlled through sensors, and allows more time efficient controls. The multi-servo actuator controls are most commonly used in industrial settings, where the level of automation or computerization is more sophisticated. Their time efficiency is the key for the reliability as their use minimizes the waste of time, which is crucial to industrial output and timely delivery of ready products and services.