What Are the Different Types Of Thin Film Coatings

Thin film coating is one of the most important industrial product that is used in the production of several other technologies including the smart phones, spectacle lenses, flat TV screens and solar cell. These coatings are applied on plastic substrates to create high value and light weight products in the manufacturing industry.

In addition being light weight, thin film coatings are durable, tough, fragile and also superior in performance when compared to other similar materials. Using plastic instead of glass allows the manufacturers to save million dollars on yearly basis. However, it should be noted that the thin film coating must be applied to the plastic to protect against severe environmental conditions.

Instructions

-

1

In reality, thin film coatings are a concept of multidisciplinary science which focuses on both chemistry and physics. Thickness of the coating depends on a number of factors but most of these films are only a few nanometres to a few microns thick.

A set of five film coatings, about 300 nm thick, are used as anti reflection material on solar panels and spectacle lenses. Comparatively, a human hair is approximately 75 microns which is equal to 75000 nanometres. It will not be wrong to say that thin film coatings are a classic example of nano engineering. -

2

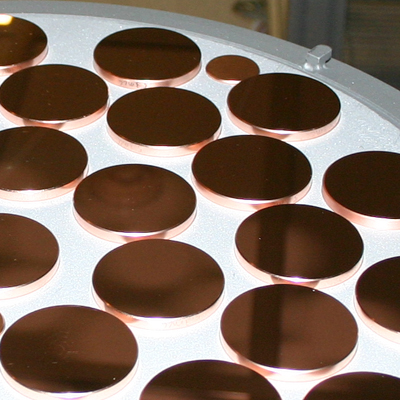

Thin film coatings are usually oxide, metallic and dielectric compounds that are used commonly in the aviation and semiconductors industry, chemical application and in the military.

Physical vapour deposition is the commonly used process in the industry to manufacture these tiny coatings. Chemical vapour deposition is another technique that is frequently used in the industry. Any film coating with maximum size of one micron in thickness is classified as the thin film coating. -

3

There are many designs and types of thin film coating. Optical coating, is perhaps the most commonly used type that is applied on laser filter and dye protection for laser surgery in hospital and medical institutions. In products like cameras, telescopes and DVD’s, anti reflective coatings are used to improve the performance.

-

4

Multilayered thin film coatings have the ability to deal with different wavelengths of light and therefore they are used frequently in optical industry. Coating made of gold, silver or aluminium with mirror like properties are commonly used in ammunition factories, barcode scanners and in photocopying machines. Ceramic thin film coatings are use to cover cutting equipment when exposed to harsh environment and chemical stress.