What is an Inventory Management System

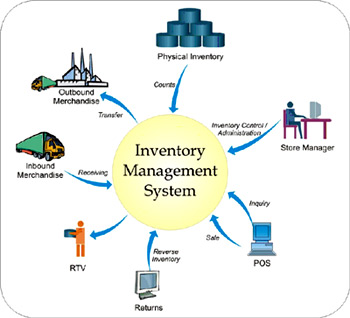

The Inventory Management System is basically a software programs that controls and manages that data related to inventories or different products at multiple locations. This system allows a company to check the level of inventory remaining in the stock and placed in different stores.

The inventory can be anything present in physical form and included in company’s asset. For instance, circulating tools, commodities, consumable items and capital equipment can all be included in inventory. If any product’s availability becomes low, the company will be informed through the Inventory Management System and the stock can be added accordingly.

Instructions

-

1

The supply chain and the marketing departments greatly rely on the Inventory Management System, as it helps in boosting company’s overall sales level. The modern systems use radio-frequency identification (RFID) tags and barcodes to provide identification information about different products.

-

2

The Inventory Management System greatly helps in sales order fulfilment process. Whenever a company receives a new order, the system informs the respective staff. As a result, the required quantity with the required specifications are prepared and shipped to the person who placed the order. This makes the process quick and efficient.

-

3

Many companies have implemented the Inventory Management System on their websites too. When people visit the company’s website and place the order, a message is delivered to the respective department that is dealing in the specific product. It also eliminates the need of a middle man greatly.

-

4

The Inventory Management System also controls the inward and outward movement of the inventory. Whenever the inventory is moved inside or outside the factory, the record is maintained using this system. As a result, it becomes easy for the managers to check the level of inventory placed in the stores and available to the customers. Moreover, it also allows the managers to make decisions related to the production levels, after having a look at the demand of a particular product.

-

5

The real time system allows the managers to speed up the processes, if the demand is too high. The transactions are transmitted to the central database right after the transaction is made for a particular product. If the demand is too high, then the managers can increase the level of production, and will deliver the products to the customers in time. Otherwise, it will become really difficult for the company to cater market needs.